D Value vs. Z Value Calculations For Medical Devices & Product Sterilization

What is sterilization?

Sterilization is any process that removes, kills, or deactivates all forms of life. Sterilization is related to the term sterile, which means a complete absence of viable microorganisms or viruses that have the potential to reproduce. Thus, sterile products that undergo sterilization are often sterilized through radiation, chemicals, or heat. Sterilization kills any microorganisms inside the products obtained during manufacturing. Sterilization occurs after the product is placed in its final packaging for dry heat sterilization, steam sterilization, ethylene oxide sterilization, vapor sterilization, liquid phase sterilization, and radiation sterilization. The last sterilization process after manufacturing is known as terminal sterilization. Please see our sterilization comparison chart for more information on which sterilization method is best for your medical device.

What are microbial growth and death kinetics?

Microbial growth is exponential. When low-level contamination occurs, it cannot be identified immediately. There is a lag time before the contaminating microbes have grown to the point where they can be measured and verify contamination. This lag phase varies between minutes to years depending upon the microbial species, product storage temperature, available nutrients, and other factors that impact microbial growth kinetics. For sterilization, relevant lag times are on the scale of minutes to hours. Once growth starts, it progresses quite rapidly. For example, a typical bacterial cell can produce over 1,300,000 cells in 8 hours! Eventually, microbial growth plateaus to a stationary phase when critical nutrients are depleted, oxygen diffusion is inhibited, or toxic metabolites accumulate. The approximate population where stationary phases exist is 10,000,000 cells/milliliter.

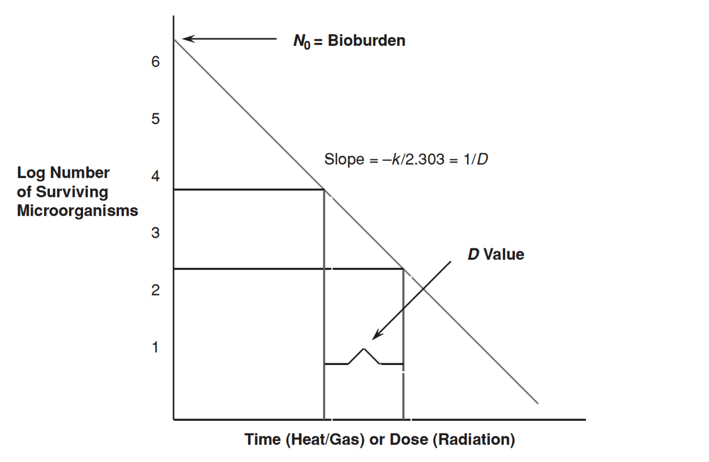

Microbial death kinetics, like growth kinetics, are exponential. Figure 17-2 below is an example of a microbial death kinetic plot. Microbial death plots can be used to calculate values and constants that describe microbial death kinetics for organisms. The most common values and constants used in microbial death kinetic studies are bioburden (the initial microbial population), D value, Z value, and F value. The relationship between bioburden, D value, and Z value is described in this article. You can find information about F value HERE.

What is bioburden?

The “bio” in bioburden refers to live biological organisms, and the “burden” in bioburden refers to the concentration of the viable biological organisms. Thus, bioburden is the concentration or quantity of microorganisms in a given area or from a particular sample. In other words, bioburden is the initial population of a microorganism before a sample or item is sterilized. The higher the concentration of viable organisms on a device or product, the higher the burden is to kill those organisms, whether it is killing the organisms through sterilization procedures or killing the organisms through the effort of the human immune system. Bioburden is measured in colony-forming units (CFU). Information on bioburden testing can be found HERE.

What is a D value?

The decimal point reduction value (D value) is the time or dose required for a one-log cycle (90% reduction) in the microbial population under lethal conditions. For medical devices and products, “lethal conditions” are the chosen sterilization method. The D value can be calculated by data collected through the survivor curve method or the fraction-negative method. The survivor-curve method establishes a D-value based on the number of surviving organisms after each sterilization procedure exposure. The fraction negative method indirectly calculates a D-value based on the fractional growth of biological indicators like bacterial spores when immersed in a growth medium. An example plot of microbial population data versus time (or dose) is shown in Figure 17-2. This plot visually demonstrates how the D value is determined from linear data. As actual microbial population versus time data isn’t linear, a linear regression line is calculated. Then the D value is calculated from this best fit line. Several complicated mathematical approaches can be alternatively used for accurately calculating the D value. However, these approaches are not covered in this article.

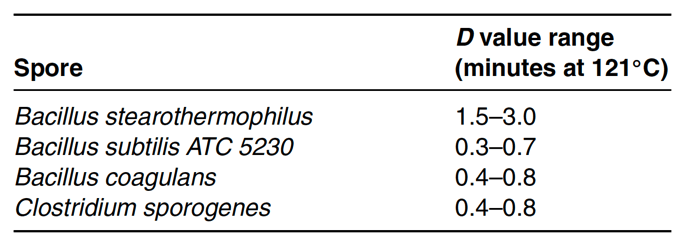

The D value is dependent on multiple factors, including the type of microorganism, temperature (or dose), and the substance containing the microorganisms. D values for various microorganisms at 121◦C are detailed in Table 17-2A below. In Table 17-2A, you can see the variance in the time necessary to kill different microorganisms under the same sterilization temperature.

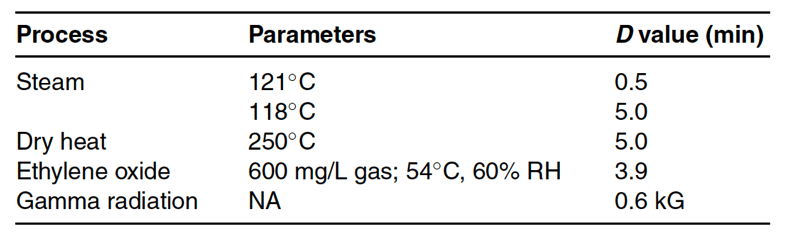

Table 17-2B below depicts the effect of common sterilization methods on the D value of the same microorganism (B. subtilis var. niger). As you can see, the effectiveness of common microbial treatments varies greatly depending upon the microorganism being eradicated. Over time, microbial D values have increased, representing the tendency of microbial life to develop resistance to the methods used to destroy them.

What is a Z-value?

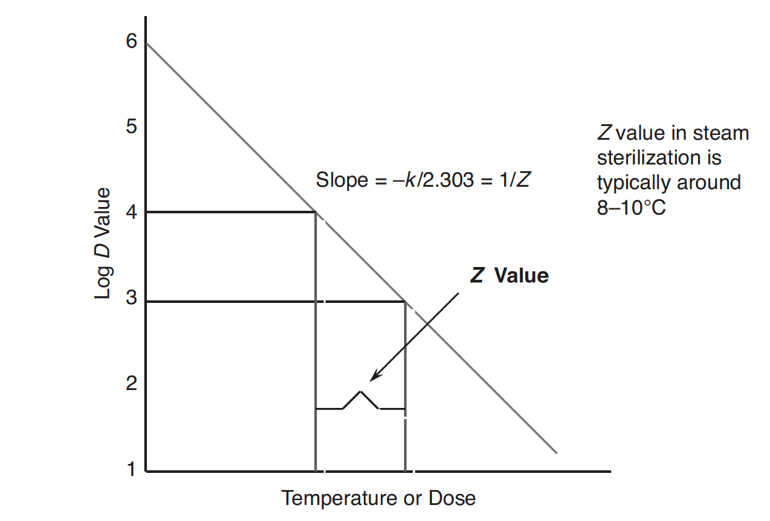

Z values are calculated based on D values. The Z value is the number of degrees (temperature) or dosage units required for a one-log reduction in the D value. In other words, the Z value is the change in the sterilization condition that affects a 10-fold (one-log) reduction in the D value. Ultimately, the Z value measures the resistance of the microorganism to death by the sterilization source. Figure 17-3 shows a logarithmic plot of the D value for a microorganism under a heat sterilization process versus temperature. The steeper the slope of the logarithmic plot, the more sterilization resistant the organism. The conventional Z value used for steam sterilization is 10ºC.

What do D values and Z values mean for the sterilization of medical devices and products?

D values are the time or dose required for a 90% reduction in the microbial population under lethal conditions. D values themselves are informative about microbial resistance to sterilization conditions. However, D values are also used to calculate Z values. They measure the resistance of the microorganism to death by the sterilization source. More specifically, the Z value is the change in the sterilization condition that affects a 10-fold (one-log) reduction in the D value. Z values are useful so that sterilization cycles for sterilization validations can cover the “worst-case scenario” for a product’s microbial contamination during manufacturing.

Summary

Overall, sterilization is any process that removes, kills, or deactivates all forms of life. Sterilization for medical devices and products is critical for ensuring patient safety during product use. D values are the time or dose required for a 90% reduction in microbial concentration via a sterilization process. Z values measure the resistance of the microorganism to death by the sterilization source. D and Z values are valuable for the sterilization cycle and sterilization validation optimization for desired product sterility. Ensure you choose a contract testing organization that can provide appropriate sterilization validations for your product needs.

Ethide Labs is a contract testing organization that specializes in Sterilization Validations and Bioburden Testing. Ethide Labs provides in-vitro cytotoxicity tests in-house and outsources in-vivo cytotoxicity work for toxicity testing of medical devices, products, and drugs. Ethide Labs also offers Microbiology Testing, Bacterial Endotoxin Testing, EO Residual Testing, Environmental Monitoring, Package Integrity Testing & Cytotoxicity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

International Organization for Standardization. Sterilization of health care products- Moist heat- Part 1: Requirements for the development, validation, and routine control of a sterilization process for medical devices. Geneva (Switzerland): ISO; 2006. (ISO 17665-1:2006/(R)2016).

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

United States Pharmacopeial Convention. <1115> Bioburden Control of Non-Sterile Drug Substances and Products. Rockville, MD, USA. 2021. (USPC <1115>).

United States Pharmacopeial Convention. <1116> Microbiological Control & Monitoring of Aseptic Processing Environments. Rockville, MD, USA. 2021. (USPC <1116>).

United States Pharmacopeial Convention. <1211> Sterility Assurance. Rockville, MD, USA. 2021. (USPC <1211>).

Share this in your social networks