Bioburden Testing For Medical Devices

What is bioburden?

Frank Noyes, M.D., defines bioburden as “the number of contaminated organisms found in a given amount of material before undergoing a sterilizing procedure.” The “bio” in bioburden refers to live biological organisms, and the “burden” in bioburden refers to the concentration of the viable biological organisms. The higher the concentration of viable microorganisms on a device or product, the higher the burden is to kill those organisms, whether it is killing the organisms through sterilization procedures or killing the organisms through the human immune system’s effort.

What is bioburden testing?

Bioburden testing measures the viable organisms present in a given sample expressed as a total viable count. This total viable count gives a value to the microbial contamination level upon or within a particular product.

Why is bioburden testing necessary?

Bioburden testing is an important quality control step that detects the level of contamination at any stage, from initial product manufacture to final distribution. As microorganisms exist on every surface (including our body), bioburden can be accidentally introduced during the manufacturing or packaging process in many ways. Some of the most common examples are contamination through the raw materials used, technicians, tubing/piping used to transfer product between development stages in a process, or the manufacturing environment itself. With such abundant contamination sources, regular bioburden testing supports the long-term control of manufacturing sites. Further, bioburden testing supports reusable medical device sterility, which can help prevent biofilm formation on implanted products.

Bioburden testing is commonly to evaluate medical devices, pharmaceuticals, packaging, raw materials, and cosmetics for the following regulatory reasons:

- To prove quality control of microbial content throughout the manufacturing process

- To validate the radiation dose or sterilization conditions for terminally sterilized product

- To determine the root cause of contamination deviations from routine production

- To validate methods for eliminating specific objectional microorganisms from a product or process

- To evaluate raw materials or finished non-sterile products for microbial content

What organisms do bioburden tests detect?

Bioburden tests detect aerobic bacteria, anaerobic bacteria, yeast, mold, and spore-forming organisms. For bacteria, gram staining of the most predominant organism recovered is performed so product developers can take that appropriate quality control steps should the bioburden test results be outside of the required limits.

How are bioburden tests performed?

Bioburden testing is governed by USP 60, USP 61, USP 62, and USP 1111. However, USP 60-USP 62 are the primary guidances followed for bioburden testing. Membrane filtration, pour-plate, surface-spread, and most-probable-number techniques are the cornerstone methods used for bioburden testing. A brief description for each bioburden testing method is given below.

Membrane filtration method:

First, appropriate dilutions of the product sample are prepared. Each of the sample dilutions is transferred to each of two membrane filters for rapid filtration. One of the membrane filters is transferred to the surface of a Soybean-Casein Digest Agar, and the other filter is transferred to the surface of a Sabouraud Dextrose Agar. Filters are washed between filtration of each sample dilution. The agar plates are then incubated between 3-7 days. Culture time and temperature are dependent upon the type of agar plate under incubation. After incubation, the Soybean-Casein Digest Agar is used to calculate total aerobic microbial count (TAMC) and the number of colony-forming units (CFUs) per gram or milliliter of the product sample. The Sabouraud Dextrose Agar is used to calculate the total combined yeasts and molds count (TYMC) and the number of CFUs per gram or milliliter of the product sample.

Most-probable-number method:

First, appropriate dilutions of the product sample are prepared. Tubes with the sample dilutions and controls are then incubated for 3 to 5 days at 30°C to 35°C. Following incubation, the vials showing microbial growth are recorded, and the most probable number of microorganisms per gram or milliliter of the product sample is quantified.

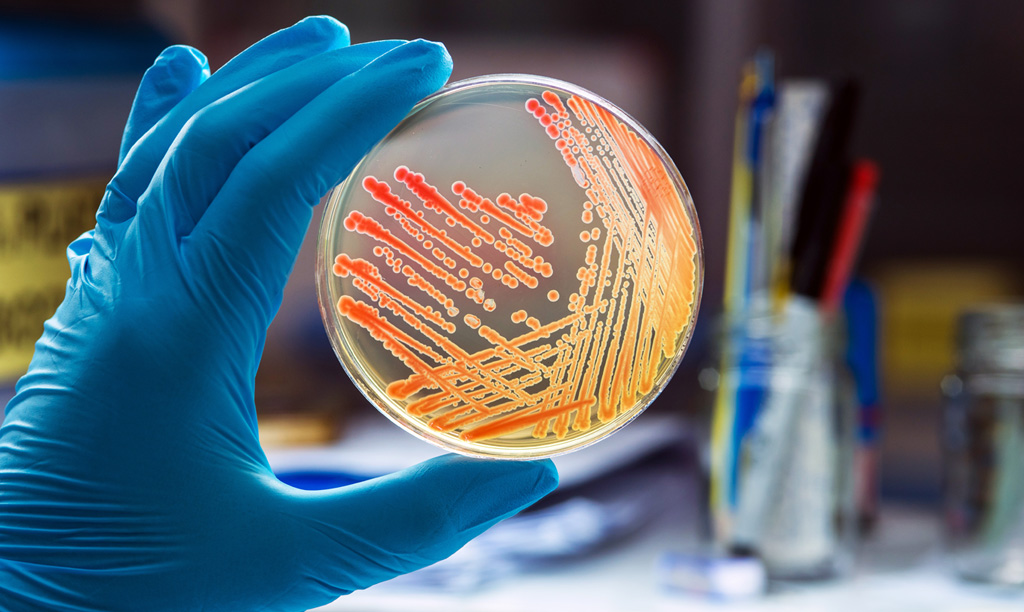

Pour-plate method:

As with the most-probable-number method, appropriate dilutions of the product sample under evaluation are prepared. Then at least two agar Petri dishes per sample dilution are made by pouring molten agar on top of the sample dilutions. The Petri dishes are incubated between 3-7 days. The incubation time and temperature depend on the agar type used. Plates with the most significant number of microorganism colonies after incubation (within a range of less than 250 for TAMC and less than 50 for TYMC) will be assessed for their CFUs per gram or per milliliter of product sample tested.

Surface-spread method:

The surface-spread method is nearly the same as the pour-plate method. The difference between the pour-plate method and surface spread method is that the agar is poured onto the sample dilution for the pour-plate method. In contrast, the sample dilution is spread onto the surface of the solidified agar for the surface-spread method.

Bioburden Test Summary

Overall, bioburden testing is a way to quantify the number and type of microorganisms present on or within a product. Bioburden testing is an important quality control step for preventing contamination from product manufacture to final distribution. Bioburden tests are performed via membrane filtration, most-probable-number, pour-plate, and surface-spread methods. These bioburden assessment methods use CFUs to calculate the CFUs per gram or per milliliter of product sample that is tested.

Ethide Labs is a contract testing organization that specializes in Bioburden Testing. Ethide Labs also offers Bacterial Endotoxin Testing, Environmental Monitoring, Sterilization Validations, Microbiology Testing, EO Residual Testing, Package Integrity Testing & Cytotoxicity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

Frank R. Noyes. Noyes’ Knee Disorders: Surgery, Rehabilitation, Clinical Outcomes. Elsevier. 2010.

United States Pharmacopeial Convention. <60> Microbiological Examination of Nonsterile Products- Tests for Burkholderia Cepacia Complex. Rockville, MD, USA. 2021. (USPC <60>)

United States Pharmacopeial Convention. <61> Microbiological Examination of Nonsterile Products: Microbial Enumeration Tests. Rockville, MD, USA. 2021. (USPC <61>)

United States Pharmacopeial Convention. <62> Microbiological Examination Of Nonsterile Products: Tests For Specified Microorganisms. Rockville, MD, USA. 2021. (USP <62>)

Share this in your social networks