Sterilization By Radiation vs. Ethylene Oxide For Medical

What is sterilization?

Sterilization is any process that removes, kills, or deactivates all forms of life. Sterilization is related to the term sterile, which means a complete absence of viable microorganisms or viruses that have the potential to reproduce. Thus, sterile products that undergo sterilization are often chemical (gas), heat, or radiation sterilized. Sterilization kills any microorganisms inside the products obtained during manufacturing. Sterilization occurs after the product is placed in its final packaging for gas, heat, or radiation sterilization. The last sterilization process after manufacturing is known as terminal sterilization. Gamma sterilization medical devices,Standard sterilization of medical devices includes gamma and ETO sterilization of medical devices. Both ETO medical device sterilization and gamma sterilization of medical devices will be covered in this article.

What is radiation Sterilization?

Sterilization by radiation is a non-thermal sterilization method that destroys microorganisms in a product with gamma radiation, beta particles (electron beam), or ultraviolet light. Other than sterile filtration, sterilization by radiation is the only other method that doesn’t rely on elevated temperature to sterilize. Sterilization by radiation is an excellent alternative and standard sterilization method for medical devices that cannot be sterilized with heat or chemicals.

What items can be sterilized by radiation?

Items sterilized with radiation are the same as items that gaseous methods can sterilize. Standard devices and materials sterilized with radiation are plastic materials, heat-labile materials, and powders. Radiation damages the nucleoproteins of microorganisms and thus is not recommended for biologics.

What are ethylene oxide and sterilization by ethylene oxide?

Ethylene oxide (ETO or EO) is a gas commonly used to sterilize medical devices and products chemically. Ethylene oxide is a potent and highly penetrating alkylating agent. These characteristics make it an extremely effective sterilizing agent and a standard sterilization method for medical devices. However, at certain levels, ethylene oxide is also capable of causing cancer. ETO medical device sterilization kills microorganisms through exposure to ethylene oxide gas under vacuum and humidity. ETO is used either as 100% ETO or in combination with carbon dioxide.

What items can be sterilized by ethylene oxide?

Standard devices and materials sterilized with ethylene oxide are plastic materials (such as plastic devices), gowning materials, heat-labile equipment, and powders. Materials that can be moist heat sterilized can also be sterilized via ethylene oxide. However, if all materials in your device or product are easily sterilized via steam, moist heat is the cheaper and easier sterilization option. ETO medical device sterilization is the standard sterilization method for medical devices that are heat-sensitive.

How is sterilization by radiation performed?

Simply speaking, sterilization by radiation is performed by exposing a product to gamma radiation, beta particles, or ultraviolet light. Microwave radiation is sometimes used for empty glass containers but is not considered a primary radiation sterilization method. Electromagnetic gamma radiation is the most effective radiation sterilization method due to its deep penetration. Often cobalt 60 high-energy photons are used for gamma radiation. Beta particles, as ionizing radiations, are not electromagnetic and less penetrative. Mechanically accelerated Strontium 90 creates exceptionally high energy levels and the beta particles (electron beams) needed for beta particle radiation. Ultraviolet light can also be used but only as a surface sterilizing method. The energy level of ultraviolet light is too weak to penetrate materials. Gamma sterilization of medical devices is the most robust option for radiation sterilization, but beta particle (e-beam) radiation is also used for product terminal sterilization.

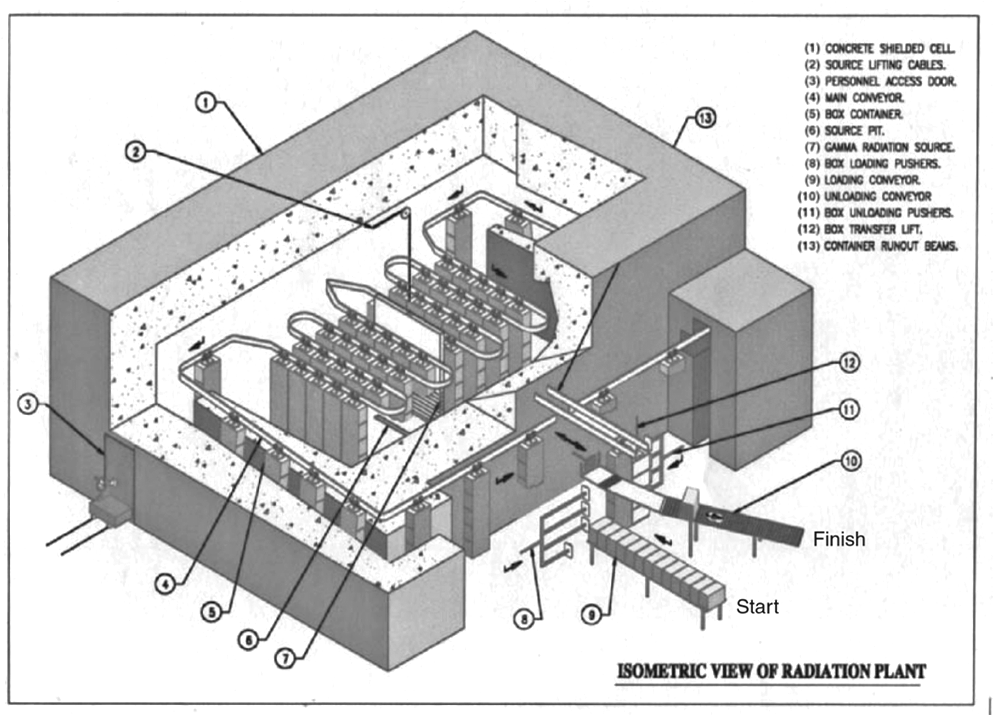

Radiation effectiveness is dependent on the radiation dosage and time exposure. A 12-D sterilization overkill approach is used in radiation sterilization. The 12-D stands for providing a radiation dose sufficient to produce a 12-log reduction in the D value of the most resistant microbial spore. Note that D value determination for radiation uses dosage rather than time. Typical D values for the most resistant bacterial spore (Bacillus pumulis) to radiation is 1.7 to 2.0 megarad (mRad). Commonly a radiation dosage will be 25 mRad, greater than 12-fold the D value of B. pumulis. During radiation sterilization treatment, dosimeters are placed at strategic locations to monitor radiation doses products receive throughout the sterilization process. When a product goes through a radiation sterilization conveyor (see Figure 1 below), the total radiation dosage is unequally distributed as items under sterilization are conveyed from start to finish. Total radiation percentages are greatest in conveyor areas closest to the source of gamma radiation. The total radiation dose for sterilization experienced by a product may be 25 mRad. Still, that radiation dosage is distributed throughout the conveyor system to avoid applying an overwhelming or damaging amount of radiation at any given time during sterilization.

Factors that affect radiation sterilization:

- D value of the biological indicator or bioburden level of the item undergoing sterilization

- Radiation strength

- Radiation dose rate

- Conveyor speed

How is sterilization by ethylene oxide performed?

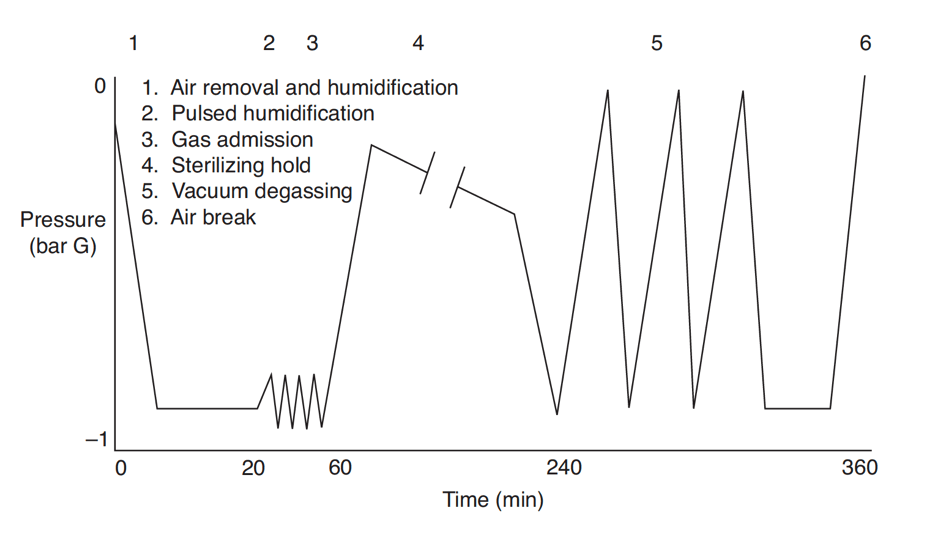

A typical ethylene oxide sterilization cycle is shown in Figure 2. The exposure time for most EO sterilizations is relatively long (around 6 hours). The gas aeration period is also lengthy, up to 24 hours or more. After loading items into an ethylene oxide sterilization chamber, a vacuum is applied. Next, the chamber is filled to the desired relative humidity. Then an appropriate concentration of EO gas is added. Items undergoing sterilization rest in the EO gas under vacuum and humidity for the desired exposure time. Finally, the gas is slowly and safely evacuated from the EO sterilization chamber, and the sterilized items are given ample aeration time to support EO off-gassing. For sterilization validations, the D value of biological indicators used for EO sterilization validations may range up to 10-fold over the range of relative humidity values.

Factors that affect EO sterilization and lethality:

- Gas concentration—Ranges is 400 to 1200 milligrams per liter

- Temperature—Temperature depends on the gas concentration. Most EO cycles range from 50◦C to 60◦C.

- Relative humidity—Humidity traditionally ranges from 35% to 80% relative humidity.

- Exposure time— Exposure time varies based on materials used, gas concentration, temperature, and relative humidity.

What are the advantages and disadvantages of radiation sterilization and ethylene oxide sterilization?

When it comes to the drawbacks of radiation sterilization, there is limited understanding of the molecular transformations in drug molecules and excipients under high-energy gamma radiation exposure. Additionally, there are not many gamma radiation or e-beam radiation sterilization centers available for bulk sterilizing products compared to other methods, such as ethylene oxide gas. Furthermore, a concern when sterilizing finished products or active pharmaceutical ingredients (APIs) with radiation is the risk of radiolytic byproduct formation (e.g., *OH) that could cause damage to the raw material, API, or product packaging system.

In contrast, the primary issue with using ethylene oxide for sterilization is its absorption into certain materials and its reaction with water or other material components to form toxic residual compounds (ethylene oxide, ethylene glycol, and ethylene chlorhydrin). These residual compounds are hazardous both to people and to the environment. Ethylene glycol is formed from ethylene oxide and water reaction, while ethylene chlorhydrin is formed from the interaction of ethylene oxide and chloride compounds. Products sterilized with ethylene oxide must meet strict EO residual limits to keep patients safe during medical device and product use. Current ISO 10993-7 EO residual limits can be found here.

Overall, radiation and ethylene oxide sterilization methods both sterilize the same materials. The advantages of radiation sterilization are that there are no toxic residuals created by radiation sterilization, no lengthy off-gassing time is needed post-sterilization, and no residual requirements need to be met for sterilized items by radiation. However, EO sterilization is far more ubiquitous than radiation sterilization methods. Thus, it is easier to find a manufacturer that can bulk-sterilize large volumes of products using EO. Also, EO machines can be found more readily in hospitals than radiation conveyors. Also, EO residuals are known and well characterized. In contrast, molecular transformations in drug molecules and excipients under high-energy gamma radiation exposure are unknown.

Summary

Overall, sterilization by radiation and sterilization by ethylene oxide are alternatives to traditional heat sterilization methods. Sterilization by radiation is a cold sterilization method that kills microbes through exposure to gamma, beta particle (e-beam), or ultraviolet radiation. In contrast, ethylene oxide sterilization uses a combination of vacuum, humidity, temperature, and gas to sterilize materials at lower temperatures than dry heat or steam sterilization methods. Unlike radiation, ethylene oxide sterilization can result in toxic residuals. Thus, any ethylene oxide sterilized medical devices or products must undergo ethylene oxide residual testing to meet FDA requirements. All in all, ensure you choose a contract testing organization that can provide appropriate sterilization validations for your product needs.

Ethide Labs is a contract testing organization specializing in Sterilization Validations & Sterility Testing. Ethide Labs also offers Microbiology Testing, Bacterial Endotoxin Testing, EO Residual Testing, Environmental Monitoring, Cytotoxicity Testing, Bioburden Testing & Package Integrity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

International Organization for Standardization. Sterilization of health care products- Moist heat- Part 1: Requirements for the development, validation, and routine control of a sterilization process for medical devices. Geneva (Switzerland): ISO; 2006. (ISO 17665-1:2006/(R)2016).

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

United States Pharmacopeial Convention. <1229.5> Biological Indicators For Sterilization. Rockville, MD, USA. 2021.(USPC <1229.5>).

United States Pharmacopeial Convention. <1115> Bioburden Control of Non-Sterile Drug Substances and Products. Rockville, MD, USA. 2021. (USPC <1115>).

United States Pharmacopeial Convention. <1116> Microbiological Control & Monitoring of Aseptic Processing Environments. Rockville, MD, USA. 2021. (USPC <1116>).

United States Pharmacopeial Convention. <1211> Sterility Assurance. Rockville, MD, USA. 2021. (USPC <1211>).

Share this in your social networks