Ethylene Oxide Residuals Exhaustive Extraction Measuring Methods

What are ethylene oxide (EtO) gas and EtO sterilization?

Ethylene oxide (also called EO or EtO) is a chemical gas commonly used to sterilize medical devices and products. Ethylene oxide is a potent and highly penetrating alkylating agent. These characteristics make it an extremely effective sterilizing agent under vacuum and humidity. In fact, approximately 20 billion medical devices are sterilized with ethylene oxide each year. Thus, ethylene oxide sterilization accounts for about half of sterilized medical supplies in the United States. However, at certain levels, ethylene oxide is also capable of causing cancer.

What is ethylene oxide (EtO) residuals testing?

The primary issue with using ethylene oxide for sterilization is its absorption into certain materials and its reaction with water (or other material components) to form toxic residual compounds (ethylene oxide, ethylene glycol, and ethylene chlorohydrin). These residual compounds are hazardous both to people and to the environment. Ethylene glycol is formed from ethylene oxide and water reaction, while ethylene chlorohydrin is formed from the interaction of ethylene oxide and chloride compounds. Products sterilized with ethylene oxide must meet strict EtO residuals limits to keep patients safe during medical device and product use. EtO residuals testing assesses medical devices and other EtO sterilized products or packaging for their residual ethylene oxide and ethylene chlorohydrin content.

What products require ethylene oxide (EtO) residuals testing?

Any items sterilized using ethylene oxide that come in physical contact with a patient require EtO residuals testing. If your device or product isn’t in physical contact with the patient, there is no need to perform EO residual testing. Due to its low-temperature conditions, ethylene oxide sterilization is well suited for medical devices with embedded electronics and medical devices that cannot withstand steam (autoclave) sterilization. Ethylene oxide is also used to sterilize the personal protective equipment and drapes used by doctors and healthcare workers. Medical device types that are sterilized with ethylene oxide range from external wound dressings to implantable stents. Other devices include heart valves, vessel closure devices, catheters, and guidewires. Products combining devices, drugs, and biologics within a single item may also be sterilized using ethylene oxide. Ethylene oxide can sterilize almost every type of plastic. Standard materials sterilized with ethylene oxide are plastics, heat-labile materials (e.g., electronics), elastomer polymeric materials, and biomaterials.

Ethylene oxide is not recommended for medical devices with embedded batteries due to the vacuum used during sterilization. Ethylene oxide sterilization is not recommended for materials sensitive to temperatures ranging from 30°C to 60°C or for medical devices made with materials that are sensitive to humidity. Polymers that are resistant to ethylene oxide sterilization are polyolefin resins such as polypropylene (PP), high-density polyethylene (HDPE), and low-density polyethylene (LDPE).

How is ethylene oxide (EtO) residual testing performed?

EtO sterilized devices are placed into one or more of three exposure categories based on the duration of contact a medical device has with a patient. These categories are designed to protect patients against EtO-related cellular toxicity that can cause varying degrees of illness and tissue damage. The categories of EtO exposure are limited exposure (less than 24 hours), prolonged exposure (1 day to 30 days), and perpetual exposure (lifetime limit). Each category has specific limits (in milligrams) that must be met. You can find current ISO 10993-7 EtO and ECH residual limits here.

Two different analysis methods for EtO residuals are used to determine the amount and type of EtO residuals in your sterilized product. These methods are simulated-use and exhaustive extraction. Evaluation of a product via either simulated-use or exhaustive extraction is sufficient to meet the ISO 10993-7 standards for EtO residual testing. Evaluation of a product via both simulated-use and exhaustive extraction is not necessary.

How is ethylene oxide (EtO) measured via exhaustive extraction?

Exhaustive extraction involves the subsequent extraction of EtO (or ECH) until the EtO (or ECH) amount is less than 10 % of the amount detected in the first extraction. Alternatively, exhaustive extraction is performed until no significant increase in cumulative EtO residue levels occurs. This extraction method is used when an entire device is in contact with a patient. Exhaustive extractions are typically performed every 24-hours until the exhaustive criteria and device use (limited, prolonged, and permanent exposure) criteria are met. For large or complex devices, exhaustive extraction may be impractical. In these situations, extracts of representative portions of the device are used to extrapolate the EtO residuals for the entire device. Four methods for measuring EtO from exhaustive extractions are detailed below.

EtO exhaustive extraction using thermal extraction

A gram of medical device or product sample is put into a capped septum vial and heated until a partial pressure of EtO gas reaches equilibrium in the vial. Next, samples of the headspace gas are injected into the gas chromatograph column. The EtO extract amount can be calculated from an EtO standard curve chromatogram. Hot samples read by gas chromatography immediately after their removal from the oven result in an error greater than 20%. On the other hand, some product materials resorb ethylene oxide gas as the vial temperature reaches room temperature. Thus, samples tested with thermal extraction will need to be injected into the column while still warm. The total ethylene oxide residuals in a sample is the sum of the EtO values obtained from each sample heating throughout reaching EtO exhaustion criteria.

EtO exhaustive extraction using ethanol followed by headspace gas analysis

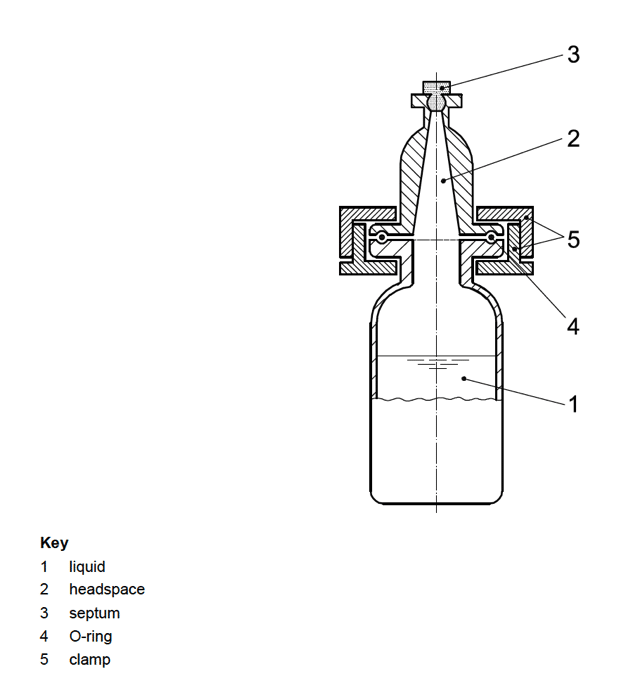

EtO standards are prepared by diluting EtO in ethanol and creating ethylene oxide concentrations ranging from 0.4 micrograms per milliliter (μg/ml) to 2.0 μg/ml. A propylene oxide (PO) in ethanol standard is also prepared at a 0.5 μg/ml concentration. A gas chromatography standard curve for EtO/PO ratio is created using headspace bottles (see Figure 1 below). The curve is created by plotting the height or area of the EO (Y-axis) and PO peaks (X-axis). The linear correlation coefficient, r, of 0.999 or better, is used for a slow of 0.5 and y-intercept of zero. For sample analysis, weigh and cut the sample into five-millimeter-long pieces for headspace bottle placement. Add PO standard solution, cap the bottle, and heat the sealed bottle with sample pieces at 70°C for 3-hours with gentle shaking. For ethylene oxide residual assessment, inject duplicate aliquots of headspace gas onto the gas chromatograph column. The EtO extract amount can be calculated from an EtO/PO standard curve.

Headspace methods may not be feasible or preferred for the testing of large or complex devices, where solvent extraction (described below) may be useful. Further, headspace methods should be avoided for EtO recovery in polymers, such as poly-(methylmethacrylate), that like to hold onto EtO residuals.

EtO exhaustive extraction using solvent(s)

For solvent extraction procedures, extraction fluid selection depends on the material composition of the device and its components. Complete EtO recovery occurs from fluids that can dissolve the sample material. Once a suitable solvent has been selected, approximately one gram of medical device (or product) is placed in a capped container with ten milliliters of solvent. Next, the immersed sample rests for 24-hours at room temperature (25°C) before being assessed via gas chromatography. For ethylene oxide residual assessment, inject duplicate aliquots of device extract onto the gas chromatograph column. The EtO extract amount can be calculated from an EtO standard response curve chromatogram.

EtO exhaustive extraction using ethanol, a bromohydrin derivative, and gas chromatography

Some medical devices, like butylated rubbers, contain bromide ions. These devices can form an ethylene bromohydrin (EBH) degradation product from residual EtO. Thus, devices samples should be assessed for EBH before bromohydrin derivative preparation.

EtO standards are prepared by diluting EtO in ethanol and creating ethylene oxide concentrations ranging from 0.4 μg/ml to 2.0 μg/ml. A PO standard is also created in ethanol at a 0.5 μg/ml concentration. A gas chromatography standard curve for EBH vs. propylene bromohydrin (PBH) is created using the PO and EtO standards mixed with hydrobromic acid. A linear correlation coefficient, r, of 0.999 or better is used for the standard curve. For EtO sample analysis, weigh a 10-to-30 milligram portion of the sample and place it into a vial with PO and hydrobromic acid. The vial stands for an hour at room temperature before being heated for 8-hours at 50°C in a water bath. The vial is further heated for 16-hours at 50°C in a laboratory oven before cooling to room temperature. Add sodium bicarbonate to the vial, shake for 30-minutes vertically, rest for 10-minutes, shake horizontally for 30 minutes, and rest for 10-minutes. Finally, the samples are centrifuged and the mixture filtered through a small Millipore filter. For ethylene oxide residual assessment, inject duplicate aliquots of filtrate onto the gas chromatograph column. The EtO extract amount can be calculated from an EtO standard response curve chromatogram.

EtO exhaustive extraction for ethylene chlorohydrin

Weigh a portion of the device (or the entire device sample), place it in a container, cover it with water, and cap the container. Next, the immersed sample rests for 24-hours before being assessed via gas chromatography. For gas chromatography assessment, agitate the sample extract for ten minutes and then inject duplicate aliquots of device extract onto the gas chromatograph column. The ECH amount can be calculated from the chromatogram’s relative peak area or peak height compared to an ECH standard response curve.

Summary

Overall, ethylene oxide (EtO) residuals testing is imperative for the regulatory approval of medical devices and products. Simulated-use and exhaustive extraction assays for EtO residuals testing ensure that EtO sterilized products are non-toxic and safe for patient use. Exhaustive extraction involves the subsequent extraction of EtO (or ECH) until the amount of EtO (or ECH) is less than 10 % of the amount detected in the first extraction. Alternatively, exhaustive extraction is performed until no significant increase in cumulative EtO residue levels occurs. This extraction method is used when an entire device is in contact with a patient. All in all, ensure you choose a contract testing organization that can support you with appropriate ethylene oxide residuals testing for your unique medical device or product needs.

Ethide Labs is a contract testing organization specializing in EO Residual Testing. Ethide Labs also offers Microbiology Testing, Bioburden Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, Sterility Testing, Environmental Monitoring & Package Integrity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

Bernhard Linke. Sterilization methods and impact on electronics in medical devices. EE Times. July 2011.

International Organization for Standardization. Biological evaluation of medical devices — Part 7: Ethylene oxide sterilization residuals. Geneva (Switzerland): ISO; 2008. (ISO 10993-7:2008).

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

Purell. Sterilization Of Polyolefins: A Methodological Overview. Lyondell Basell Industries.2011.

United States Food & Drug Administration. Ethylene Oxide Sterilization for Medical Devices. Digital Article. September 2020.

Share this in your social networks