Depyrogenation by Radiation vs. Sterilization by Radiation For Medical Devices

What is sterilization, and why is it essential for sterile products?

Sterilization keeps patients safe from toxins and microbial illnesses when therapies or devices are consumed or used. Sterilization is any process that removes, kills, or deactivates all forms of life. Under the strictest definition of sterility, an item or product is sterile when there is the complete absence of viable microorganisms (bacteria, yeasts, viruses, and molds). For regulatory purposes, sterility is defined by acceptance criteria based on calculated contamination probability. An acceptable level of contamination risk for most items is the probability of a single contaminated product out of a million manufactured products. However, sterility criteria may be more stringent or lax depending upon the intended use of the medical device or product.

Commonly, sterile products undergo sterilization processes that utilize chemicals, heat, radiation, or filters. Sterilization kills any microorganisms products collect during manufacturing. A less common version of sterilization is vapor phase sterilization.

What is depyrogenation, and why is depyrogenation needed for sterile products?

Parenteral products must be sterile and pyrogen-free. Even if a product is sterile, it can still contain pyrogens. Depyrogenation is a process that removes pyrogens. The most prevalent and problematic pyrogens are the bacterial endotoxins found in the outer cell walls of gram-negative bacteria. Thus, depyrogenation is a process that will either destroy or remove bacterial endotoxins. Products can accumulate pyrogens from raw materials or other parts of the manufacturing process. The best pyrogen removal or destruction processes are product-dependent. Standard depyrogenation methods are dry heat, rinsing, and filtration.

What are pyrogens, endotoxins, and lipopolysaccharide (LPS)?

Pyrogens are molecules or substances that cause a feverous reaction when they enter the human body. Endotoxins are the most common type of pyrogen. Endotoxins come from the cell walls of gram-negative bacteria. The endotoxins themselves are molecules with both fat components and complex sugar components. The presence of fat and sugar components is why endotoxins are also known in scientific literature as lipopolysaccharides (LPS). LPS is the biologically active portion of an endotoxin. In other words, LPS is the part of the endotoxin that triggers the innate immune system and causes illness in humans. Parenteral products and devices are contaminated with endotoxin through Gram-negative bacterial cells or cell wall fragments containing LPS. Lipopolysaccharide’s structure allows it to stick to hydrophobic (water-repellant) and hydrophilic (water-loving) surfaces. Thus, LPS components easily attach to molecules and proteins in solutions or material surfaces, causing endotoxin contamination. LPS also sticks to itself to form LPS chains known as aggregates.

What is radiation sterilization (sterilization by radiation)?

Sterilization by radiation is a non-thermal sterilization method that functions by destroying any microorganisms in a product with gamma radiation, beta particles (electron beam), x-ray, or ultraviolet light. Other than sterile filtration, sterilization by radiation is the only other sterilization method that doesn’t rely on elevated temperature to sterilize. Sterilization by radiation is an excellent alternative for products that cannot be sterilized with heat or chemicals.

What items can be sterilized by radiation?

Items sterilized with radiation are the same as items that gaseous methods can sterilize. Standard devices and materials sterilized with radiation are plastics, heat-labile materials, glass, and powders. Radiation damages the nucleoproteins of microorganisms and thus is not recommended for biologics.

How is sterilization by radiation performed?

Simply speaking, sterilization by radiation is performed by exposing a product to gamma radiation, beta particles, or ultraviolet light. Microwave radiation is sometimes used for empty glass containers but is not considered a primary radiation sterilization method. Electromagnetic gamma radiation is the most effective radiation sterilization method due to its deep penetration. Often cobalt 60 high-energy photons are used for gamma radiation. Beta particles, as ionizing radiations, are not electromagnetic and less penetrative. Mechanically accelerated Strontium 90 creates exceptionally high energy levels and the beta particles (electron beams) needed for beta particle radiation. Ultraviolet light can also be used but only as a surface sterilizing method. The energy level of ultraviolet light is too weak to penetrate materials. Gamma sterilization is the most robust option for radiation sterilization, but beta particle (e-beam) radiation is also used for product terminal sterilization.

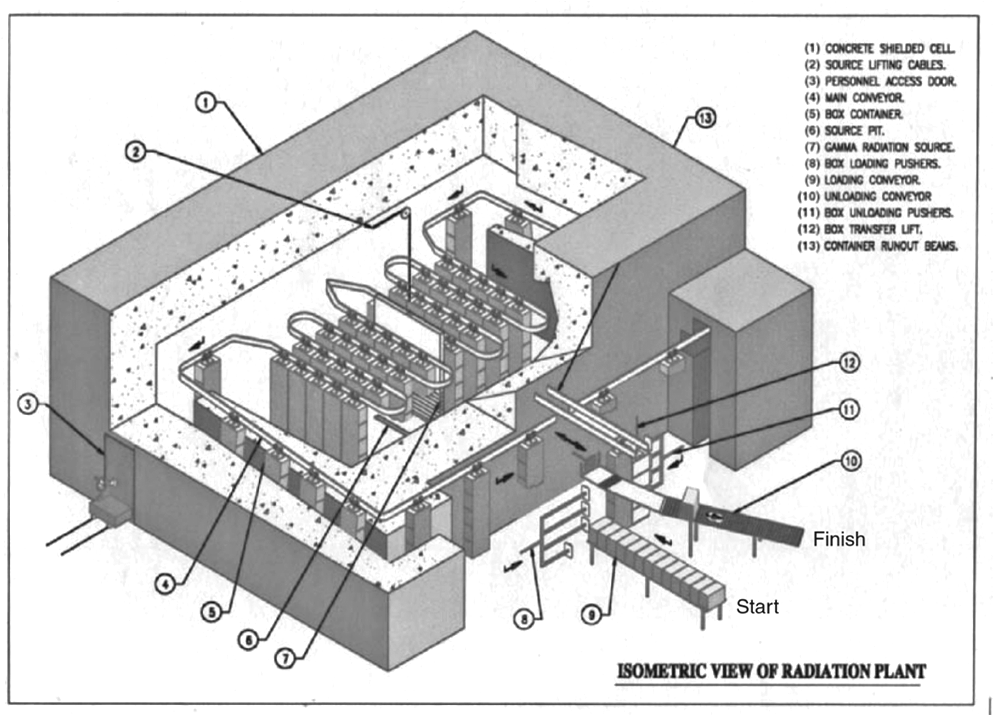

Radiation effectiveness is dependent on the radiation dosage and time exposure. A 12-D sterilization overkill approach is used in radiation sterilization. The 12-D stands for providing a radiation dose sufficient to produce a 12-log reduction in the D value of the most resistant microbial spore. Note that D value determination for radiation uses dosage rather than time. Typical D values for the most resistant bacterial spore (Bacillus pumulis) to radiation is 1.7 to 2.0 megarad (mRad). Commonly a radiation dosage will be 25 mRad, greater than 12-fold the D value of B. pumulis. During radiation sterilization treatment, dosimeters are placed at strategic locations to monitor radiation doses products receive throughout the sterilization process. When a product goes through a radiation sterilization conveyor (see Figure 1 below), the total radiation dosage is unequally distributed as items under sterilization are conveyed from start to finish. Total radiation percentages are greatest in conveyor areas closest to the gamma radiation source. The total radiation dose for sterilization experienced by a product may be 25 mRad. The total radiation dosage is distributed throughout the conveyor system to avoid applying an overwhelming or damaging amount of radiation at any given time during sterilization.

Factors that affect radiation sterilization:

- D value of the biological indicator or bioburden level of the item undergoing sterilization

- Radiation strength

- Radiation dose rate

- Conveyor speed

What are the problems with sterilization by radiation?

There is limited understanding of the molecular transformations in drug molecules and excipients under high-energy gamma radiation exposure. Additionally, there are not many gamma radiation or e-beam radiation sterilization centers available for bulk sterilizing products compared to other methods, such as ethylene oxide gas. Furthermore, a concern when sterilizing finished products or active pharmaceutical ingredients (APIs) with radiation is the risk of radiolytic byproduct formation (e.g., *OH) that could cause damage to the raw material, API, or product packaging system.

How is depyrogenation by radiation performed?

Radiation is often a slow depyrogenation process. Products are depyrogenated through exposure to radiation from a radioisotope, such as cobalt 60 or cesium 137, or electron beams. Recently a medium energy 2 MeV electron beam has been used for depyrogenation of USP-grade Type I glass vials. The advantages of utilizing radiation for sterilization and depyrogenation are that this method has low chemical reactivity, doesn’t require heat exposure, and only a few variables must be controlled for the process. However, irradiation can negatively affect certain grades of plastics and glass.

What are the differences between using radiation for depyrogenation vs. sterilization?

Methods for radiation depyrogenation and sterilization are essentially the same. In products with a high pyrogen burden, the total amount of radiation required to depyrogenate products will be higher than traditional sterilization procedures. Bacterial Endotoxin Tests (BETs) can be used to determine the pyrogen burden (endotoxin levels) within products before depyrogenation.

Summary

Medical devices, products, and therapies must be sterile and pyrogen-free. Sterilization is any process that removes, kills, or deactivates microbes, whereas depyrogenation is a process that removes pyrogens. The most prevalent and problematic pyrogens are the bacterial endotoxins found in the outer cell walls of gram-negative bacteria. Radiation sterilization and depyrogenation processes are cold methods that kill microbes through exposure to gamma, beta particle (e-beam), or ultraviolet radiation. Sterilization by radiation works well for heat-sensitive materials. However, irradiation can negatively affect certain grades of plastics and glass. All in all, ensure you choose a contract testing organization that can provide appropriate sterility testing for your product needs.

Ethide Labs is a contract testing organization specializing in Sterilization Validations and Sterility Testing. Ethide Labs also offers Microbiology Testing, Bioburden Testing, EO Residual Testing, Bacterial Endotoxin Testing, Cytotoxicity Testing, Environmental Monitoring & Package Integrity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

Mitra, A. et al., Abstract: Depyrogenation of glass vials using 2 MeV electron beam by reflection and scattering method. ETDEWEB. 2014.

Samya El-Magdy Salama and Elham, A. Mobarez. Depyrogenation Methods. Egypt. J. Chem. Environ. Health, 1(1):540-551. 2015.

United States Pharmacopeial Convention. <1116> Microbiological Control & Monitoring of Aseptic Processing Environments. Rockville, MD, USA. 2021. (USPC <1116>).

United States Pharmacopeial Convention. <1211> Sterility Assurance. Rockville, MD, USA. 2021. (USPC <1211>).

United States Pharmacopeial Convention. <1229> Sterilization of Compendial Articles. Rockville, MD, USA. 2021. (USPC <1229>).

United States Pharmacopeial Convention. <1229.10> Radiation Sterilization. Rockville, MD, USA. 2021. (USPC <1229.10>).

Share this in your social networks