USP 788 Particulate Matter Testing Methods

What is particulate matter testing, and why is particulate matter testing important for injectable products?

When it comes to particulate matter testing for injectables, the United States Pharmacopeia (USP) aligns its guidelines with both the European and Japanese Pharmacopeia. Particulate matter refers to undissolved particles (other than gas bubbles) that are present in injectable solutions. This particulate matter is not an intentional addition to the parenteral formulation. Just as unintentional microbes in injectables are avoided and regulated to prevent patient illness, unintentional, non-biological particles are regulated in injectable formulations to prevent unwanted toxicity, infection, or side effects. For those creating parenteral products for veterinary use, solutions used for irrigation alone, or radiopharmaceutical preparations, particle matter regulation requirements of USP 788 do not need to be met. If your injectable product uses a filter before patient administration, your injectable may be exempt from particulate matter guidelines, provided supporting scientific data justify such an exemption. Note that this article will use parenteral and injectable synonymously. Thus, a small-volume injection and a small-volume parenteral are synonymous terms. Two primary methods are used to detect particulate matter in a sample. A light-obscuration particle count test is the first of these two methods. The second method is a microscopic particle count test. Additional information on how each test is performed is detailed below. We also have articles detailing ophthalmic solution particulate matter testing and therapeutic protein particle matter testing.

Should I use USP 788 method 1 or method 2 for particle count testing of my injectable product?

Light-obscuration particle count testing is preferred to detect subvisible particles in injections and parenteral infusions. However, microscopic particle count testing should assess parenteral preparations with reduced clarity or increased viscosity (such as emulsions, colloids, and liposomal formulations). Microscopic particle count testing is also helpful for products that tend to produce air or gas bubbles during sampling. In some cases, both particulate matter test methods will be needed to confirm subvisible particle counts. And select injectable formulations may be difficult to assay via both traditional particulate matter testing methods. In cases when the viscosity of the test preparation is high, a quantitative dilution will be made to decrease viscosity, as necessary, to allow the particulate analysis to be performed.

All in all, viscous products that are not easily diluted should be assayed using microscopic particle count testing, as air bubbles can be incorrectly identified as particulate matter using light-obscuration particle count testing. Moreover, all emulsions, colloids, liposomal formulations, and suspensions should be evaluated using microscopic particle count testing to ensure the accuracy of the results. Otherwise, light-obscuration testing can mistake suspension and emulsion droplets for particulate matter.

How is particle count testing method 1 performed?

Light-obscuration particulate matter testing uses a liquid particle counter machine that, based on the principle of light scattering, allows for an automated determination of the size of particles in a sample and the number of particles according to size. The liquid particle counter is calibrated using dispersions of spherical particles in particle-free water. These spherical particles are of known sizes between 10 microns (μm) and 25 μm. Before use, all glassware and testing equipment are rinsed with particle-free water. Samples of particle-free water are tested following equipment set-up, ensuring that no more than 25 particles of 10 μm or greater are identified in particle-free controls in replicate. If more particles are identified, the testing equipment will be cleansed again and recalibrated prior to sample testing. Common electronic particle counter issues can be found HERE.

For testing, each sample’s contents are mixed by slow inversion. Care is taken not to introduce air bubbles into examined preparations. Gas bubbles are further eliminated by allowing samples to stand for 2 minutes after inversion or through sonication. For small-volume Parenterals (less than 25 milliliters in volume), the contents of 10 or more units are combined in a cleaned container to obtain a volume not less than 25 milliliters (mL). Powders for parenteral use are reconstituted with particle-free water or with an appropriate particle-free solvent when particle-free water is not suitable. Injectables with a volume of 25 mL or more are tested individually. For pharmacy bulk packages “Not for Direct Infusion,” calculate the test result on a portion equivalent to the maximum labeled dose. For example, if the average particle count per mL is 5, you would multiply the particle count per mL by ten to obtain the particle count for the 10-mL maximum dose. In this example, the particle count for the 10-mL maximum dose is fifty particles. Products meant to hold a drug product and a solvent should be tested as directed for large-volume parenterals or small-volume parenterals, depending on container volume.

The number of samples must be adequate to provide a statistically sound assessment. For parenterals with a volume of 25 mL or more, less than ten individual units may be tested.

After careful mixing, remove four portions, no less than 5 mL each, and count the number of particles equal to or greater than 10 μm and 25 μm. Calculate the mean number of particles for the preparation to be examined.

Once particles have been counted, calculate the mean number of particles for the sample examined. For light obscuration particle count tests, there are two test criteria. For sample preparations with a volume of more than 100 mL, the first test criteria apply. Samples with a volume of fewer than 100 mL use the second test criteria. In the first test criteria, the sample complies with the particle count test if the average number of particles present in the test units does not exceed 25 particles per mL equal to or greater than 10 μm and does not exceed 3 particles per mL equal to or greater than 25 μm. In the second test criteria, the sample meets the test criteria if the average number of particles tested does not exceed 6000 particles per container equal to or greater than 10 μm and does not exceed 600 particles per container equal to or greater than 25 μm. If the average number of particles exceeds the limits, test the parenterals by the microscopic particle count test.

How is particle count testing method 2 performed?

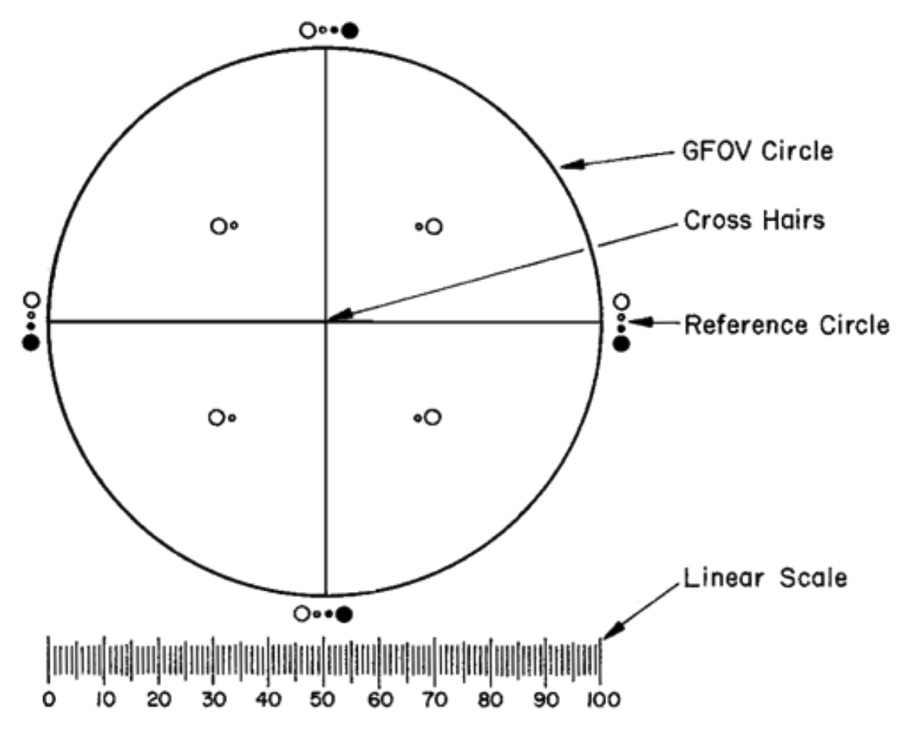

Microscopic particle count testing uses a binocular microscope, a filter assembly for retaining particulate matter, and a membrane filter for sample examination. The microscope will have an ocular micrometer with a graticule (see Figure 1 reproduced from Figure 1 of USP 788 below). The ocular micrometer is calibrated using a stage micrometer certified by either a domestic or international standard institution. Additionally, two illuminators (one internal and one external) are needed for the microscope assembly.

Prior to use, all glassware and testing equipment are rinsed with particle-free water. Samples of particle-free water are tested following equipment set-up, ensuring that no more than 20 particles of 10 μm or greater are identified in particle-free controls in replicate. If more particles are identified, the testing equipment will be cleansed again and recalibrated prior to sample testing.

For testing, each sample’s contents are mixed by slow inversion. For small-volume Parenterals (less than 25 milliliters in volume), the contents of 10 or more units are combined in a cleaned container to obtain a volume not less than 25 milliliters (mL).

Powders for parenteral use are reconstituted with particle-free water or with an appropriate particle-free solvent when particle-free water is not suitable. Parenterals with a volume of 25 mL or more are tested individually.

The number of samples must be adequate to provide a statistically sound assessment. For parenterals with a volume of 25 mL or more, less than 10 individual units may be tested.

After the injectable samples have been prepared, the filter holder is wetted with particle-free water. The total volume from an injectable sample or pooled sample is transferred to the filtration funnel. Then a vacuum is applied until the surface of the membrane filter is free of liquid. Next, the membrane filter is placed in a Petri dish and allowed to air-dry. After the membrane filter has dried, the entire membrane filter is scanned under the microscope. The total number of particles on the membrane filter equal to or greater than 10 μm, and the number of particles equal to or greater than 25 μm are counted. The particle sizing is determined by estimating the equivalent diameter of the particle in comparison with the 10 μm and 25 μm reference circles on the graticule. In microscopic particle count testing, semiliquid or otherwise amorphous materials that have the appearance of a stain or discoloration on the membrane filter cannot be sized. These materials show a gelatinous or film-like appearance. If gelatinous or film-like materials appear, test a solution sample by particle count test method 1.

Once particles have been counted, calculate the mean number of particles for the sample examined. For microscopic particle count tests, there are two test criteria. For sample preparations with a volume of more than 100 mL, the first test criteria apply. Samples with a volume of fewer than 100 mL use the second test criteria. In the first test criteria, the sample complies with the particle count test if the average number of particles present does not exceed 12 particles per mL equal to or greater than 10 μm and does not exceed 2 particles per mL equal to or greater than 25 μm. The sample meets the second test criteria if the average number of particles present in the units tested does not exceed 3000 per container equal to or greater than 10 μm and does not exceed 300 per container equal to or greater than 25 μm.

Summary

Overall, particulate matter testing is an important microbiology test for injectables. Unintentional, non-biological particles are regulated in injectable formulations to prevent unwanted toxicity, illness, or side effects in patients following treatment. Two tests can be used for particulate matter testing, a light-obscuration particle count test (method 1) and a microscopic particle count test (method 2). Light obscuration particle count methods are used except when preparations are too cloudy or viscous for accurate particle detection. Microscopic particle count testing is used when preparations are too cloudy or viscous for light obscuration particle count methods. All in all, when developing your injectable product, ensure you choose a contract testing organization that can support you with appropriate microbiology testing for your unique medical device or product needs.

Ethide Labs is a contract testing organization specializing in Particulate Matter Testing and Microbiology Testing. Ethide Labs also offers EO Residual Testing, Sterility Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, Bioburden Testing, Package Integrity Testing & Environmental Monitoring services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

United States Pharmacopeial Convention. <788> Particulate Matter In Injections, In Vitro. Rockville, MD, USA. 2021. (USPC <788>).

Share this in your social networks