Top 3 ISO-Approved Methods For Radiation Sterilization Dose Setting

How does the United States Food and Drug Administration (FDA) define sterile?

Under the strictest definition of sterility, an item or product is sterile when there is the complete absence of viable microorganisms (bacteria, yeasts, viruses, and molds). For regulatory purposes, sterility is defined by acceptance criteria based on calculated contamination probability. An acceptable level of contamination risk for most items is the probability of a single contaminated product out of a million manufactured products. However, sterility criteria may be more stringent or lax depending upon the intended use of the medical device or product.

What are sterilization validations, and why are they important?

Since the sterility of a medical device or product is based on acceptance criteria, the process that a product or device undergoes to become sterile must be validated to prove that sterility acceptance criteria are consistently met. Sterility can be assured only using a validated sterilization process under current good manufacturing practices (cGMP). Sterility cannot be demonstrated by reliance on periodic sterility testing of final products alone. Thus, sterilization validations are tests that accumulate data about a sterilization process and statistically prove that the sterilization process can consistently sterilize medical devices or products under “worst-case scenario” conditions.

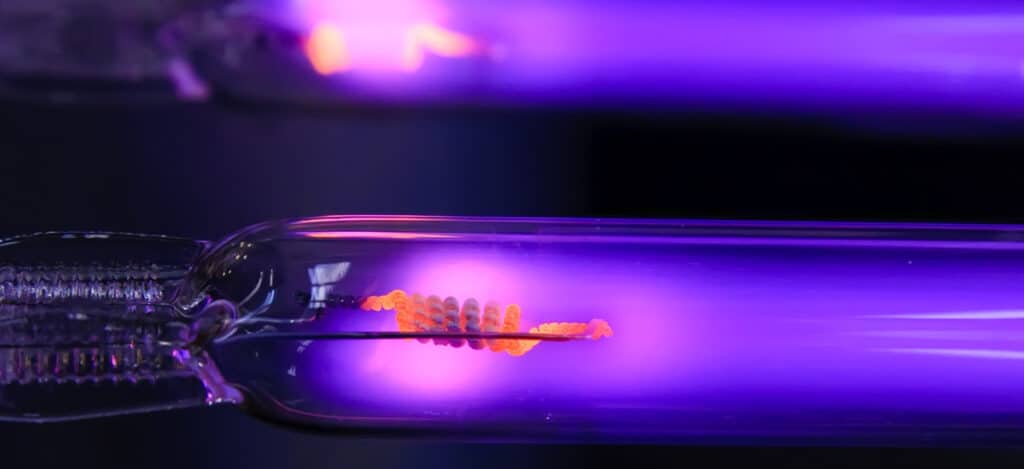

What is radiation sterilization (sterilization by radiation)?

Sterilization by radiation is a non-thermal sterilization method that functions by destroying microorganisms in a product with gamma radiation, beta particles (electron beam), x-ray, or ultraviolet light. Other than sterile filtration, sterilization by radiation is the only other sterilization method that doesn’t rely on elevated temperature to sterilize. Sterilization by radiation is an excellent alternative for products that cannot be sterilized with heat or chemicals.

What items can be sterilized by radiation?

Items sterilized with radiation are the same as items that gaseous methods can sterilize. Standard devices and materials sterilized with radiation are plastics, heat-labile materials (e.g., electronics), and powders. Radiation damages the nucleoproteins of microorganisms and thus is not recommended for biologics.

How are radiation sterilization dosages determined?

Radiation sterilization validation design begins with selecting the radiation type (typically gamma radiation) and radiation dose that will effectively sterilize the medical device or product. Care must be taken to select a radiation dose that doesn’t adversely impact a material’s functionality or quality. Often radiation dosages fall within a range that includes the minimum dose needed for efficacy and the maximum radiation dose the materials can withstand and maintain their integrity. There are three International Organization for Standardization (ISO) approved approaches to radiation dose setting. These ISO-approved approaches are Method 1, Method 2, and VDmax Method. Factors such as production batch size, knowledge of the product bioburden, and the product material’s sensitivity to radiation determine which dose setting method is best to use.

What is ISO radiation dose setting Method 1?

Method 1 bases radiation dosage upon a verified microbial population. Indeed, the radiation dose is set based on historical data or a literature-derived standard radiation resistance for the verified microbial population. Data for the sterilization resistance of the microbial population can also be used to determine radiation dose, if available. A verification dose study must be performed for dosages set based on historical data or literature to confirm that the standard microbial resistance represents a more severe microbial challenge than the actual microbial population on the products to be sterilized.

What is the ISO-approved VDmax Method for radiation dose setting?

The VDmax Method, like Method 1, requires microbial population knowledge and dose verification testing. However, unlike Method 1, the VDmax Method relies on verified product bioburden ranges (e.g., <1000 CFUs per item) for radiation dosage selection.

What is ISO radiation dose setting Method 2?

Method 2 is a complex method for radiation dose determination. In contrast to Method 1 and the VDmax Method, Method 2 does not require information about the products’ microbial population to set the sterilization dose. Instead, Method 2 exposes products to a series of incremental radiation dose exposures to establish a dose at which approximately one out of one hundred samples will be nonsterile. While not the final sterilization dose, the one nonsterile product in one hundred radiation dosage provides enough information to extrapolate the final radiation sterilization dose. While microbial population information is not necessary for establishing the final radiation sterilization dosage for Method 2, microbial population information is needed for routine monitoring and control of the verified sterilization process.

Summary

All in all, medical product and device sterility can be assured only by using a validated sterilization process under current good manufacturing practices (cGMP). Sterilization validations prove that set sterility acceptance criteria (of one unsterile product in a million or less) are consistently met. Radiation sterilization is a non-thermal method of sterilization that functions through destroying microorganisms in a product with gamma radiation, beta particles (electron beam), x-ray, or ultraviolet light. Radiation sterilization is used for medical devices and products that cannot withstand chemical or heat sterilization methods. Depending upon factors such as production batch size, knowledge of the product bioburden, and the product material’s sensitivity to radiation, radiation sterilization cycle dosages are determined through one of three ISO-approved methods. Method 1 and VDmax Method use information about the product’s microbial population to determine radiation dosage (microbial population type and bioburden concentration, respectively). In contrast, Method 2 exposes products to a series of incremental radiation dose exposures to establish a dose at which approximately one out of one hundred samples will be nonsterile. This radiation dose is then used to extrapolate the final radiation sterilization dose. The amount of reliable information you have on your manufactured product’s bioburden population will determine which ISO-approved method is best to determine the radiation sterilization dose for your products. No matter which radiation dosage determination method you select, ensure you choose a contract testing organization that can provide appropriate support with radiation dose selection and sterilization validations for your unique medical device or product needs.

Ethide Labs is a contract testing organization specializing in Sterilization Validations & Microbiology Testing. Ethide Labs also offers Bioburden Testing, Bacterial Endotoxin Testing, EO Residual Testing, Sterility Testing, Cytotoxicity Testing, Environmental Monitoring & Package Integrity Testing services for medical device companies and allied industries. Ethide is an ISO 13485 certified facility.

References

United States Pharmacopeial Convention. <1229> Sterilization of Compendial Articles. Rockville, MD, USA. 2021. (USPC <1229>).

United States Pharmacopeial Convention. <1229.10> Radiation Sterilization. Rockville, MD, USA. 2021. (USPC <1229.10>).

Share this in your social networks